Starter has officially participated in a successful KickStarter campaign, and as a result has received a fully functional SLA 3D Printing Machine. This is great news considering the fact that with this new equipment requisition, Starter will be producing fully functional, SLA 3D prints very soon.

Up until now Starter has only offered FDM style 3D printing.

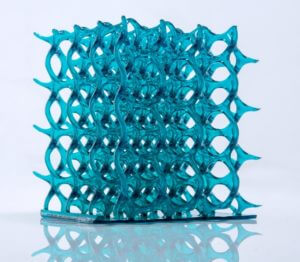

SLA printing (Stereolithography), also known as photo-solidification resin printing is another form of 3D printing technology. Similar to FDM printing, SLA printing produces parts in a layer-by-layer fashion using photo-polymerization, a process by which light causes chains of molecules to link, forming polymers. Those polymers then make up the body of a three-dimensional solid.

The advantage that this style of printing has over traditional FDM printing is the capability of producing super detailed parts with exceptional quality and smoothness, far greater than standard FDM machines are capable of creating.

With SLA printing, parts are “drawn” out of a resin bath layer-by-layer as opposed to being deposited on a build platform by filament forced through a hot extruder nozzle. This allows abstract and uniquely shaped objects, which would normally require extensive support structures if printed on a FDM machine, to be printed with super high-realistic quality.

T3D, a startup company based out of Taipei, has produced the SLA machine procured by Starter. The unique ability of this printer in particular is it’s ability to cure the photo-polymer resin using the light generated by a standard smart phone screen. Most common SLA machines use special lasers to cure the photo-polymer resin layer by layer. By creating a printer that uses the light generated by smart phones and tablets, T3D has significantly reduced the cost of SLA printing technology, placing it in the hands of many makers.

Check out the T3D Kickstarter campaign here.

Check back soon for more updates regarding Starter and SLA printing technology.